Why IP66 Stage lights Are Heavier and More Expensive: A Detailed Comparison with IP20, IP54 & IP66 lights

- Introduction

- Understanding IP Ratings and Their Impact on Stage Lights

- What Are IP Ratings?

- Why Heat Dissipation Matters

- Structural and Material Characteristics of IP66 Lights

- Robust Housing Design

- Advanced Heat Sink Technologies

- Protective Coatings

- Comparison: IP20, IP54, and IP66 Lights

- Challenges of IP66 Heat Dissipation Systems

- How LQE is Innovating

- Frequently Asked Questions

- Why are IP66 waterproof lights more expensive than IP20 lights?

- Can IP66 lamps be used indoors?

- How does LQE ensure the stability of their optimized designs?

- What is the lifespan of an IP66 stage lights?

- Are there lightweight alternatives to IP66 lights?

- Conclusion

- Tags

Introduction

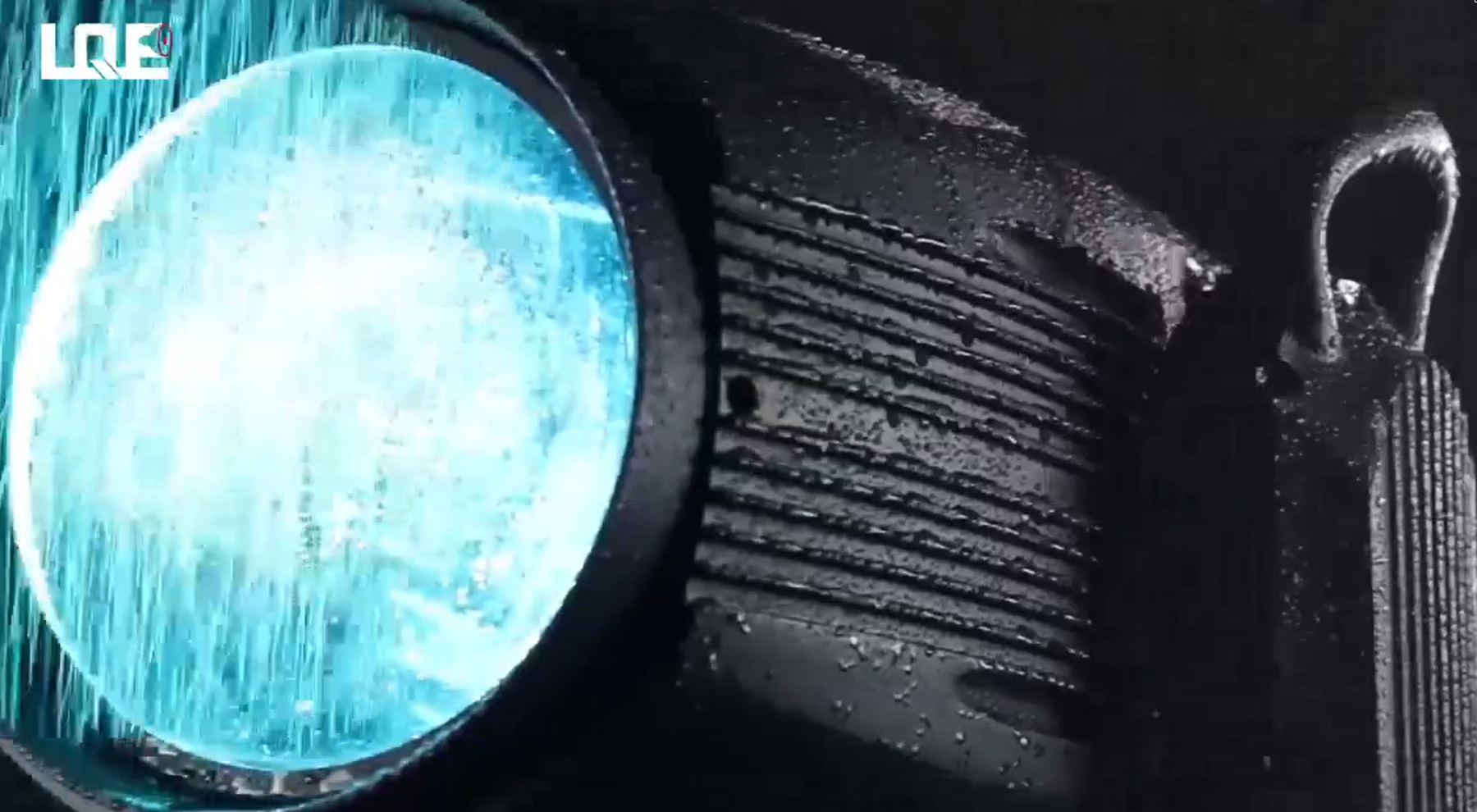

When it comes to stage lighting, protection ratings play a critical role in determining the performance, durability, and cost of lamps. Among the various IP ratings, IP20, IP54, and IP66 are the most commonly discussed. However, the heat dissipation structures and materials of these lamps differ significantly, especially when comparing indoor-friendly IP20 lamps to the rugged, outdoor-ready IP66 versions. These differences make IP66 lamps heavier and more expensive. In this article, we’ll explore the structural and material characteristics of IP66 lights, compare them with IP20 and IP54 lamps, and uncover how manufacturers like LQE are optimizing materials and structures to achieve lighter, more cost-effective designs without compromising stability.

Contact us: [email protected] for more details.

Understanding IP Ratings and Their Impact on Stage Lights

What Are IP Ratings?

IP (Ingress Protection) ratings classify the level of protection a lamp provides against solids (like dust) and liquids (like water). The two-digit code indicates specific levels of protection:

- IP20 : Protected against solid objects larger than 12.5mm but offers no protection against water.

- IP54 : Provides limited protection against dust ingress and splashes of water from any direction.

- IP66 : Fully dust-tight and can withstand powerful water jets, making it ideal for outdoor use.

Why Heat Dissipation Matters

Efficient heat dissipation is crucial for maintaining lamp performance and longevity. Heat buildup can lead to component failure, especially in high-power stage lamps. This is where the design and materials of the lamp’s housing and heat sink become vital.

Structural and Material Characteristics of IP66 Lights

Robust Housing Design

IP66 lamps are designed with:

- Sealed Enclosures : To ensure complete dust-tightness and water resistance, IP66 lamps use high-quality gaskets and seals.

- Thicker Walls : The housing is often made from aluminum or stainless steel, which provides durability but adds weight.

Advanced Heat Sink Technologies

The heat dissipation system in IP66 lamps includes:

- Larger Heat Sinks : To offset the thermal challenges posed by sealed enclosures, IP66 lamps feature extensive fins or integrated thermal channels.

- Thermally Conductive Materials : These materials, like copper or advanced alloys, improve heat transfer but are costlier.

Protective Coatings

To withstand outdoor elements, IP66 lamps often include:

- Corrosion-Resistant Coatings : Such as anodized aluminum or powder coatings.

- UV-Resistant Layers : To prevent degradation from prolonged exposure to sunlight.

Comparison: IP20, IP54, and IP66 Lights

| Feature | IP20 | IP54 | IP66 |

|---|---|---|---|

| Protection Level | Basic (Indoor use only) | Limited dust and water resistance | Complete dust and water proof |

| Housing Material | Lightweight plastic or metal | Medium-grade aluminum | Heavy-duty aluminum/steel |

| Heat Sink Design | Minimal | Moderate | Extensive |

| Weight | Light | Moderate | Heavy |

| Cost | Low | Moderate | High |

Challenges of IP66 Heat Dissipation Systems

-

Thermal Management

- Sealed enclosures trap heat, requiring larger and more advanced heat sinks.

- Active cooling systems may be needed in some cases, adding complexity.

-

Weight and Bulk

- The use of thick, durable materials increases overall weight.

- Larger heat sinks and protective layers add bulk.

-

Cost Implications

- High-grade materials and complex designs significantly raise manufacturing costs.

-

Assembly Precision

- Ensuring a perfect seal against dust and water involves meticulous engineering, which further increases costs.

How LQE is Innovating

LQE has been at the forefront of optimizing materials and structures for stage lamps, particularly in IP66 models. Their strategies include:

-

Material Substitution

- Replacing traditional metals with lightweight, thermally efficient composites.

-

Optimized Design

- Using computational simulations to design heat sinks that maximize efficiency while reducing weight.

-

Advanced Coatings

- Employing thinner but more effective protective coatings to cut down on weight.

-

Cost Reduction Initiatives

- Partnering with suppliers to source high-quality materials at lower costs.

Frequently Asked Questions

Why are IP66 waterproof lights more expensive than IP20 lights?

The robust construction, advanced heat dissipation systems, and protective coatings of IP66 lamps significantly increase manufacturing costs compared to IP20 lamps.

Can IP66 lamps be used indoors?

Yes, but their higher cost and weight make them less practical for indoor use unless specific protection is required.

How does LQE ensure the stability of their optimized designs?

LQE employs rigorous testing protocols, including thermal simulations, environmental tests, and real-world usage scenarios.

What is the lifespan of an IP66 stage lights?

With proper maintenance, IP66 lamps typically last longer than IP20 lamps due to their robust design and superior protection.

Are there lightweight alternatives to IP66 lights?

While alternatives exist, they often compromise on protection or heat dissipation efficiency. LQE’s innovations aim to bridge this gap.

Conclusion

The weight and cost disparities between IP20 and IP66 stage lamps stem from the technical challenges and material requirements of IP66 designs. By understanding the structural and material differences, manufacturers and consumers can make informed decisions. Companies like LQE are leading the charge in optimizing these systems, achieving a balance between cost, weight, and performance. Whether you’re lighting a grand outdoor stage or a small indoor venue, choosing the right IP rating ensures safety, durability, and efficiency.

Tags

- IP66 lights fixtures

- Stage lighting heat dissipation

- IP20 vs IP66

- LQE lamp optimization

- Outdoor stage lights

- IP54 comparison

- Heat sink technologies

- Lighting industry insights

- Lamp cost optimization

- Dustproof and waterproof lighting

- 7 Expert Strategies to Design Captivating Outdoor Lighting for Theme Parks & Architectural Landscapes

- Why IP65 Waterproof Pixel Strobe Lights Are a Game-Changer for Large Concerts: 7 Crucial Benefits Unveiled

- Why Are Outdoor Stage Lamps Getting Smaller and Lighter? The Game-Changing Trend in Stage Lighting

- What Is a Good CMY for Stage Lighting? A Complete Guide

- Why Do We Need High-Power Moving Head Beam Lights with CMY for Performances & Large-Scale Outdoor Theme Events?

1000w

Do You Supply After-Sale Service?

LQE lighting offers 7x24 hrs systematic SOP customer support with dedicated personnel, ensuring quick and comprehensive assistance for stage lighting needs.

Distributor

What types of companies can become LQE distributors?

We welcome partnerships with companies that have experience in the entertainment, AV, lighting, or stage equipment industries. Whether you are a local reseller, importer, system integrator, or project contractor, we are open to exploring win-win cooperation.

What is your typical lead time for distributor orders?

Our standard production lead time is 15–30 working days depending on order volume and customization requirements. For stocked models or repeat orders, we can offer shorter delivery times.

Can LQE help with product training and technical guidance?

Absolutely. We offer remote training sessions, user manuals, installation guides, and continuous technical support to help your team understand and sell our products with confidence.

What support does LQE offer to its distributors?

We provide our distributors with a full package of support, including:

Marketing materials and product catalogs

Technical training and manuals

Fast-response after-sales service

Exclusive regional pricing and policies (for qualified partners)

Priority access to new products and updates

Want to learn more information?

[Reach out to us and receive professional guidance, a personalized quote, and the best solution for your needs.]

Linkedin

YouTube

Whatsapp: +8618924548390

TikTok